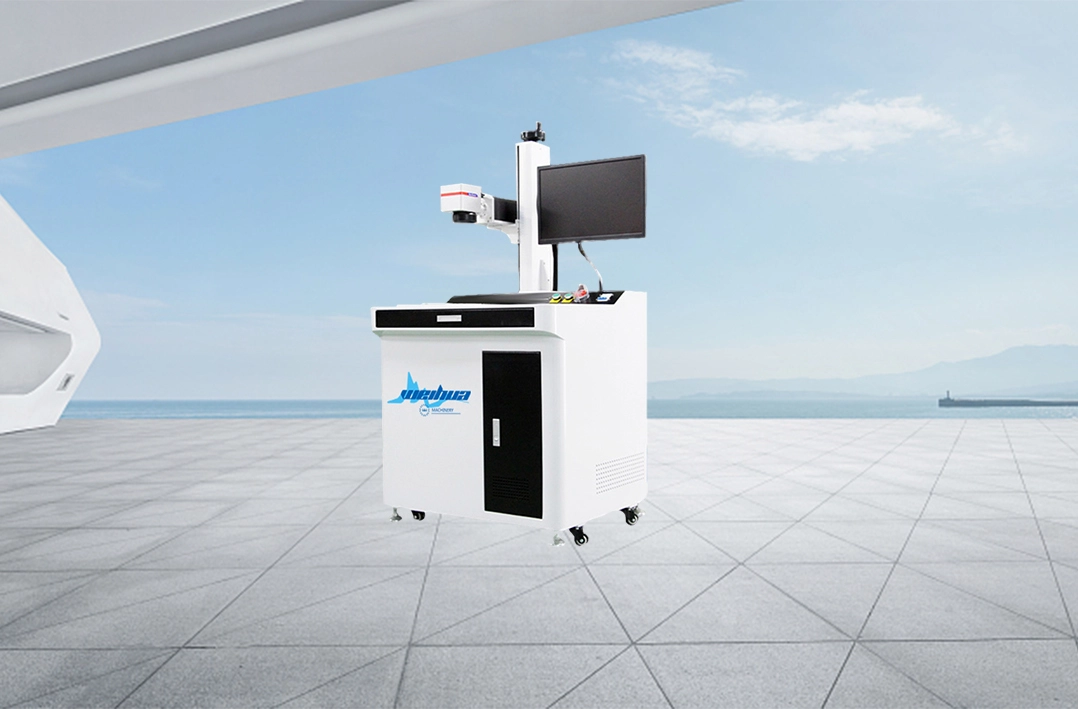

Laser marking machines have revolutionized the manufacturing industry with their precision and versatility. These powerful tools offered by Jinan Weihua Machinery & Equipment Co., Ltd, have become essential for a wide range of applications. In this article, we will delve into the fascinating world of laser marking machines, exploring their capabilities, applications, and why they are considered indispensable in modern manufacturing.

Laser marking machines are synonymous with precision. These machines, such as large-scale laser marking machines, utilize the focused power of a laser beam to create markings on various surfaces. The process involves removing or altering a small layer of material to leave a permanent, high-contrast mark. This precision is achieved through the use of advanced optics and computer-controlled technology.

One of the standout features of laser marking machines is their ability to mark on both metallic and non-metallic surfaces. They can etch intricate designs, serial numbers, barcodes, and logos on materials such as stainless steel, aluminum, plastics, ceramics, and more.

Unlike traditional marking methods that may involve physical contact or harsh chemicals, laser marking is contactless and non-destructive. It preserves the integrity of the material, making it ideal for industries where material quality is crucial.

Laser marking machines are known for their speed and efficiency. They can complete complex marking tasks in a matter of seconds, making them indispensable for high-volume production lines.

The versatility of laser marking machines extends far beyond basic engraving. They find applications in a myriad of industries, proving their worth in diverse scenarios.

In the industrial sector, laser marking machines are used to mark parts and components with important information like serial numbers, manufacturing dates, and QR codes. This ensures traceability and quality control.

The medical industry benefits from laser marking's precision, using it to mark surgical instruments, medical devices, and implants. Laser markings on medical equipment ensure patient safety and traceability.

The electronics industry relies on laser marking for labeling semiconductor chips, printed circuit boards, and electronic components. The high precision and legibility of laser markings are essential in this field.

In automotive and aerospace manufacturing, laser marking is used for part identification, labeling, and compliance with industry standards. It ensures the durability and safety of critical components.

At Jinan Weihua Machinery & Equipment Co., Ltd, as a reliable laser machine manufacturer, we understand that every industry and application has unique requirements. That's why we offer tailored laser marking solutions to meet your specific demands.

We provide a range of laser types and powers, allowing you to choose the one that best suits your marking needs. Whether it's a fiber laser for metal engraving or a CO2 laser for non-metal surfaces, we have you covered.

Our laser marking machine for sale comes equipped with user-friendly software that allows you to design and control your markings with precision. We also offer training and support to ensure you make the most of your equipment.

For seamless integration into your production processes, our laser marking machines can be customized to work in tandem with your existing equipment. This enhances productivity and reduces downtime.