In recent years, the manufacturing industry has witnessed a remarkable shift towards advanced technologies. One such technology that has gained significant traction is laser machines. Laser machines are being widely used to perform various tasks in manufacturing processes, including plastic manufacturing. Their precision, versatility, and efficiency make them the perfect choice for shaping and engraving plastic materials.

1. Precision and Accuracy: Laser machines offer unparalleled precision and accuracy in plastic manufacturing. Their ability to create intricate designs with minimal margin for error ensures high-quality end products. This precision is especially crucial when manufacturing components that require tight tolerances and intricate features.

2. Fast and Efficient: Laser machines can significantly speed up the manufacturing process. Their high processing speed, combined with precise cutting and engraving capabilities, allows for faster production times. This efficiency translates into reduced production costs and increased output for manufacturers.

3. Versatility: Laser machines for plastic are versatile tools that can work with a wide variety of plastic materials. From acrylics and polycarbonates to ABS and PVC, laser machine can handle various types of plastics without compromising the quality of the finished product. This versatility makes laser machines suitable for a range of industries, including automotive, electronics, medical, and more.

4. Sustainability: In today's environmentally conscious world, laser machines for plastic offer sustainable manufacturing solutions. The precise cutting and shaping abilities of laser machines result in minimal waste generation. Additionally, the low energy consumption of laser technology contributes to a reduced carbon footprint, making these machines environment-friendly.

1. Cutting and Shaping: Laser machines have revolutionized the cutting and shaping processes in plastic manufacturing. With their high precision and accuracy, these machines can create intricate designs and patterns on plastic materials with ease. Whether it is cutting complex shapes, creating fine details, or achieving smooth edges, laser machines offer unmatched precision and efficiency.

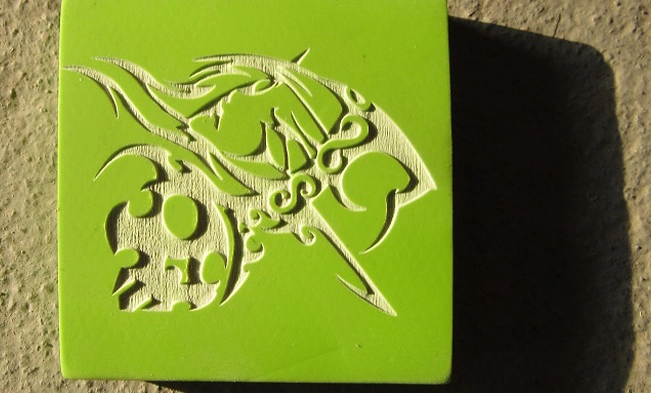

2. Engraving and Marking: Laser machines are widely used for engraving and marking plastic materials. The laser beam can etch text, logos, serial numbers, or any other desired design onto the surface of the plastic. This capability is invaluable for branding, identification, or personalization purposes. Compared to traditional methods, laser engraving and marking offer higher precision, durability, and versatility.