Stone laser engraving machine is specially designed for granite, marble engraving. Marble, granite, and other stones are generally very heavy. The split structure of the stone laser engraving machine cleverly avoids this problem. The stone does not need to be placed on the machine platform, but on the ground or a small cart. This way, there is no need to worry about the problem of machine deformation caused by the stone being too heavy.

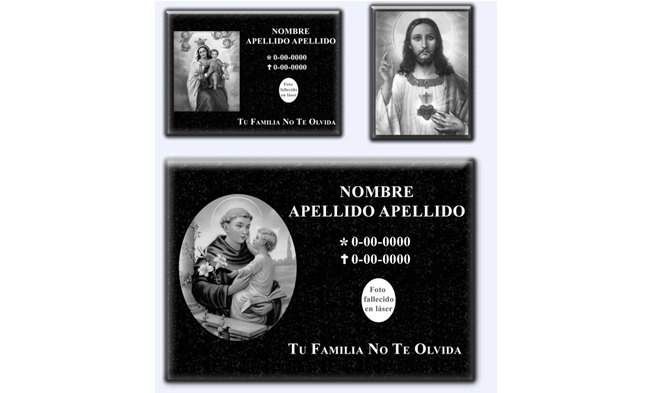

The stone laser engraving machine adopts a special split structure and is usually equipped with a low-power laser tube, such as 60W or 80W. This is because low-power laser tubes can produce smaller laser spots and finer laser lines, which helps to achieve high-precision engraving. It is especially suitable for the fine processing of materials such as jade plates, pebbles, agate stones, jade, marble, granite, portraits, and tombstones. Its engraving effect is clear and there is no problem of yellowing, discoloration, or falling off.

In addition to stone carving, it can also process other non-metal materials like a regular laser engraving machine. However, because it uses a low-power laser tube, the stone laser engraving machine is more suitable for high-precision engraving tasks rather than cutting.

The stone laser engraving machine is widely used for engraving text, images, or patterns on various stone materials such as marble, jade, granite, artificial marble, agate, pebbles, tombstones, and stone decorative items. It is known for its high engraving accuracy, fast speed, and resistance to yellowing and fading, which adds aesthetic and collectible value to the stones and facilitates their preservation and inheritance.