It can cut metal materials such as stainless steel, carbon steel, galvanized sheet within 2mm, as well as pine board, pine board, multilayer board, ebony, rosewood and other mahogany boards within 15mm, and can also cut various cardboards, EVA, hibiscus board, Osong board and other non-metallic materials.

Mainly used in sheet metal processing, metal advertising word cutting, stainless steel kitchenware processing, advertising industry, thin metal cutting and other industries.

This mixing and cutting machine is a must-have equipment for advertising, photo frame making, creative furniture, template making, decoration and other industries.

| Model | WH-13090M | WH-1325M |

| Work size | 1300*900mm | 1300*2500mm |

| Laser Power | 600W (150w/180w/200w/300w/500w) | |

| Transmission mode and drive system | Standard configuration: belt drive + well-known brand "Yankong" stepper motor and drive system Advanced configuration: ball screw transmission + Japanese Yaskawa servo motor and drive system | |

| Laser Type | CO2 sealed laser tube,10.6um | |

| Cooling Way | Water cooling chiller 150w-180w machines use CW-5200 chiller 200w-600w machines use CW-6000AN chiller | |

| Work Table | Thickened blade workbench | |

| Laser output power | 0-100% controlled by software | |

| Positioning accuracy | ±0.02mm/m | |

| Cutting thickness | 40mm | |

| Cutting speed | 20m/min | |

| Control Software | Professional Ruida control software | |

| Supported file formats | BMP,PLT,DST,DXF,and AI etc | |

| Supported Software | CORELDRAW,PHOTOSHOP,AUTOCAD,AUTOCAD | |

| Supplied equipment | Exhaust fan and air intake duct Air compressor Water Chiller | |

| Control Systerm | Offline control | |

| Voltage | AC110-220V±10%/10A,50-60HZ | |

| Rated Power | <2000W | |

| Package | Wood box | |

| Warranty | The whole machine is guaranteed for 12 months | |

| Item | Materials | Cut or Not |

| Metal | ·Stainless steel | √ |

| ·Carbon steel √ | √ | |

| ·Galvanized steel √ | √ | |

| ·Copper/brass | × | |

| ·Aluminum | × | |

| Non-metallic materials | ·Acrylic | √ |

| ·Wood | √ | |

| ·MDF | √ | |

| ·Plywood | √ | |

| ·Plastic | √ | |

| ·Foam | √ | |

| ·PVC | √ | |

| ·Rubber | √ |

Material | Thickness(mm) | Auxiliary Gas | 220w (mm/s) | 300w (mm/s) | 500w (mm/s) | 600w (mm/s) |

| Stainless steel | 0.5 | oxygen | 70 | 100 | 144 | 180 |

| 1 | oxygen | 18 | 60 | 96 | 110 | |

| 2 | oxygen | 8 | 25 | 48 | 60 | |

| 3 | oxygen | 4 | 10 | 18 | 25 | |

| Carbon steel | 0.5 | oxygen | 33 | 110 | 180 | 220 |

| 1 | oxygen | 25 | 80 | 144 | 150 | |

| 2 | oxygen | 10 | 30 | 60 | 80 | |

| 3 | oxygen | 5 | 15 | 24 | 35 |

| Laser power/Thickness | 5mm | 10mm | 20mm | 30mm |

| 220w | 31-33mm/s | 13-15mm/s | 5-7mm/s | 4-5mm/s |

| 300w | 45-47mm/s | 19-21mm/s | 7-9mm/s | 6-8mm/s |

| 500w | 70-80mm/s | 31-36mm/s | 13-15mm/s | 12-14mm/s |

| 600w | 90-95mm/s | 40-45mm/s | 15-20mm/s | 14-16mm/s |

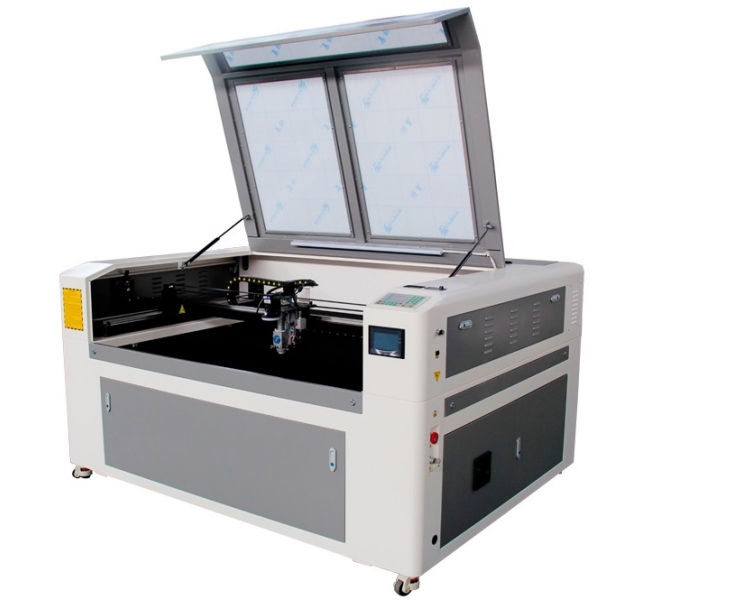

1. The machine shell is made of 1mm thick iron plates welded together, making it sturdy and durable. It has high stability, effectively eliminating vibrations during high-speed cutting.

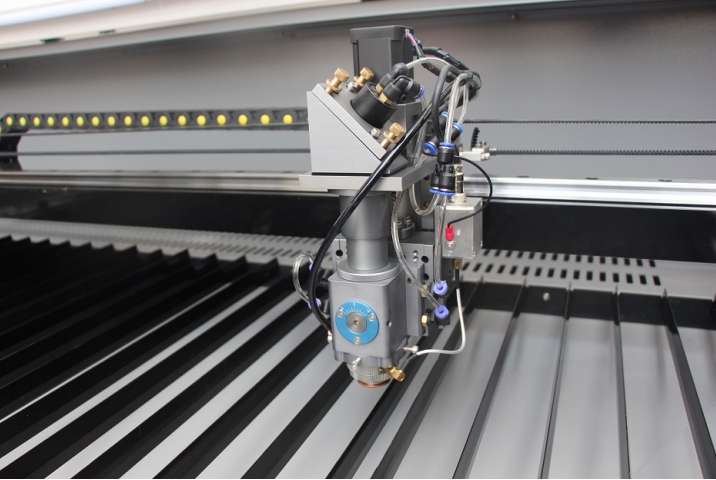

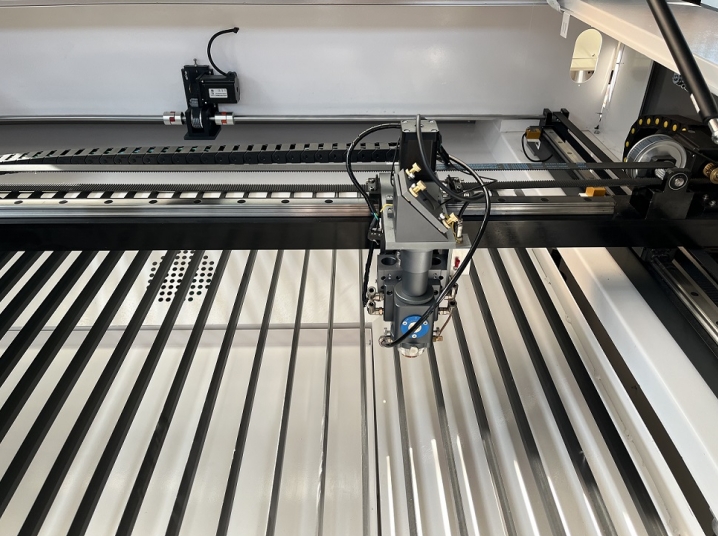

2. Dynamic auto-focusing laser head: Due to the typically uneven surfaces of large metal sheets, the auto-focus function allows the laser head to dynamically self-adjust, maintaining an equal distance from the sheet to ensure cutting effect and precision.

3. Advanced color LCD screen + USB port + DSP offline control, supports cutting of metal and non-metal materials. Supports USB drive and USB connection.

4. Thickened blade platform: The platform has a large load capacity, suitable for cutting various heavy and hard materials, meeting diverse laser processing needs.

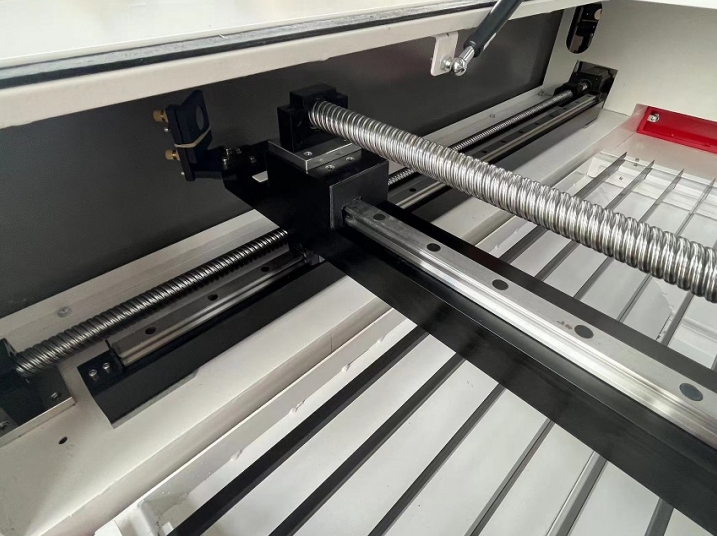

5. Linear guide: Imported high-precision linear guide and professional optical system with dust-proof and automatic lubrication features, offering high speed, low noise, high precision, and long lifespan.

6. Exhaust system: Considering environmental requirements, we have equipped the machine with an exhaust system to absorb cutting powder and dust, directly expelling dust outside, resulting in no dust, no odor, making the cutting process more environmentally friendly.

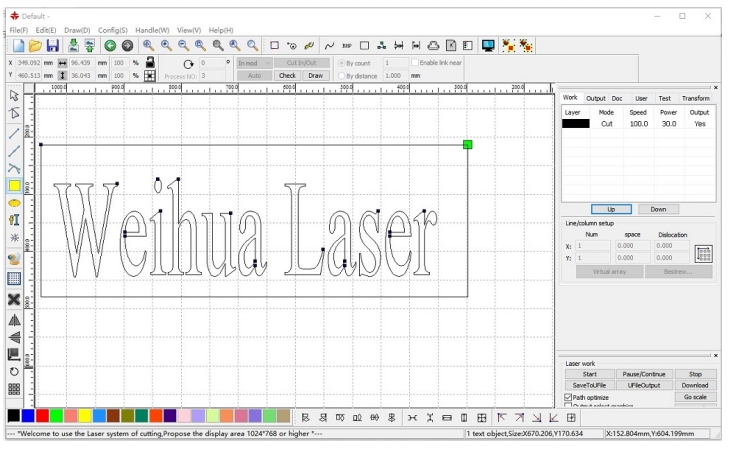

7. Professional laser cutting software: Designed specifically for cutting metal and non-metal, with high compatibility supporting any computer operating system. Supports DXF, PLT, G code, and many graphics.

8. American imported brand II-IV focusing lens and reflective lens, with high light transmission rate, maximizing laser utilization.

9. Special chiller for laser cutting machine: Uses CW-5200 / CW-6000 high-power water cooling system with alarm protection function and temperature monitoring function, protecting the water circulation from shutdown. CW-5200 is used for 150w-180w cutting machines, CW-6000 for 200w-300w cutting machines.

* Belt transmission: Uses the well-known drive belt, containing metal materials, non-slip, fire-resistant, and long-lasting.

* Stepper motor: Uses the renowned "YAKOTEC" stepper motor and drive system, with digital timing and analog quantum control of laser power, resulting in minimal error and high repeat accuracy.

* Ballscrew transmission Taiwan 25,mm TBI ballscrew.

* Japan servo motor, making higher precise positioning and smooth operation

Red light preview function: Because laser is invisible light, we achieve laser path preview and pre-positioning by adding a 'red light indicator.

Border function: The border function can simulate the walking path of laser cutting. Before cutting, perform a prewalk to ensure the cutting position's accuracy and improve material utilization.

Lens with water cooling: For 500w and 600w laser cutter, Its focusing lens and the reflecting lens have water-cooling protection, which can effectively prevent aging caused by high lens temperatures. This can extend the lens's lifespan and reduce operating costs.